The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Palletizer machine: fast and stable bag stacking

Looking for a palletizer machine that combines speed and precision? Votech designs and manufactures high-performance palletizing machines for the automatic palletizing of bags. As a specialist in automated packaging lines, we deliver complete palletizing solutions for powders, minerals, animal feed, and products from the agricultural and horticultural sectors.

Our palletizing systems integrate seamlessly into both new and existing production lines. Votech palletizers are available in different configurations and are suitable for both overlapping and non-overlapping stacking of bags. With their robust design, they are easily combined with a pallet roller conveyor or other transport systems. Thanks to our modular engineering, each machine can be quickly adapted to changing production needs or new packaging formats—creating a flexible system that grows with your business.

Home » Palletizers

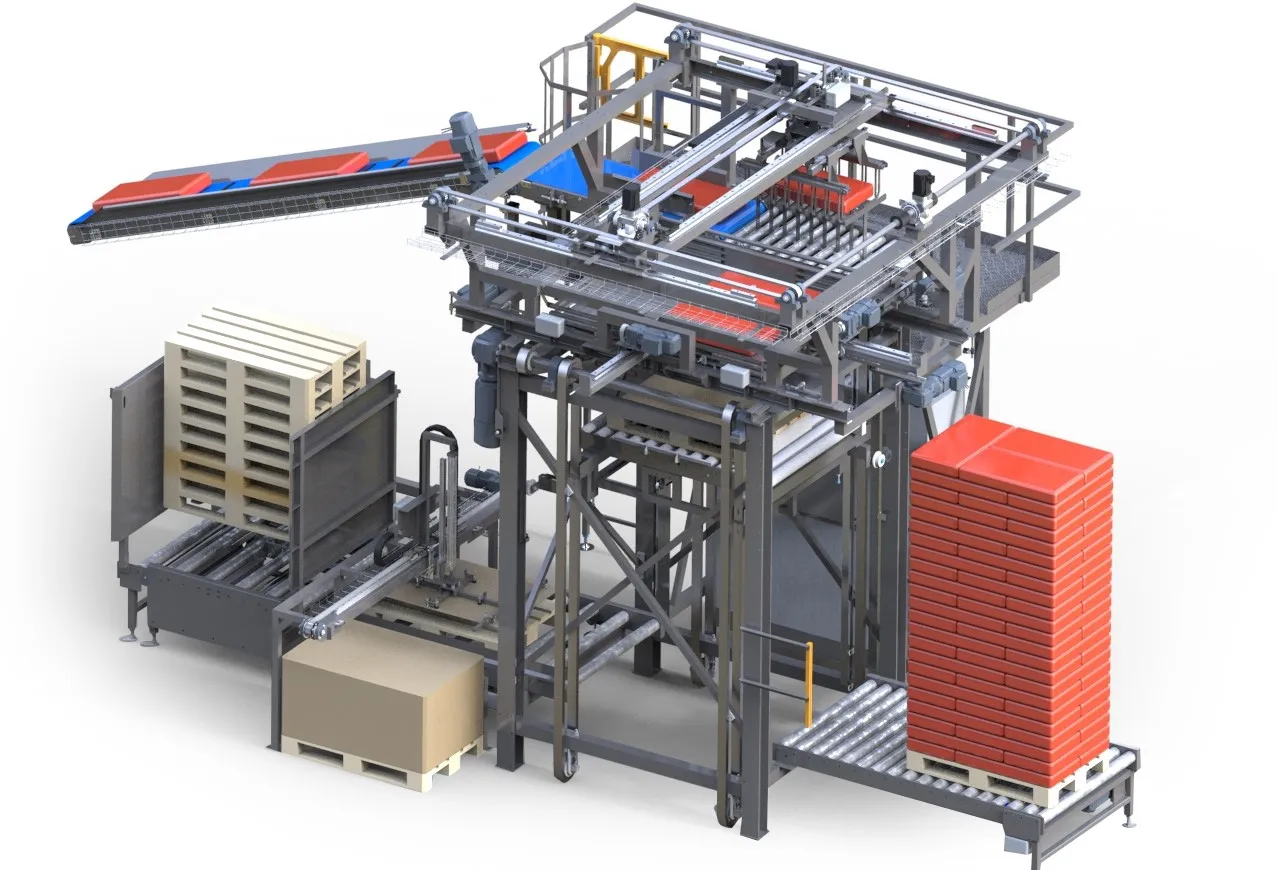

Designed with a special rotating head that ensures a controlled and accurate bag stacking.

- Stacking box to keep the load within the pallet size without overhang, for optimal efficiency in warehouses and containers and no bag damage or product loss;

- Can stack both overlapping and non-overlapping bags.

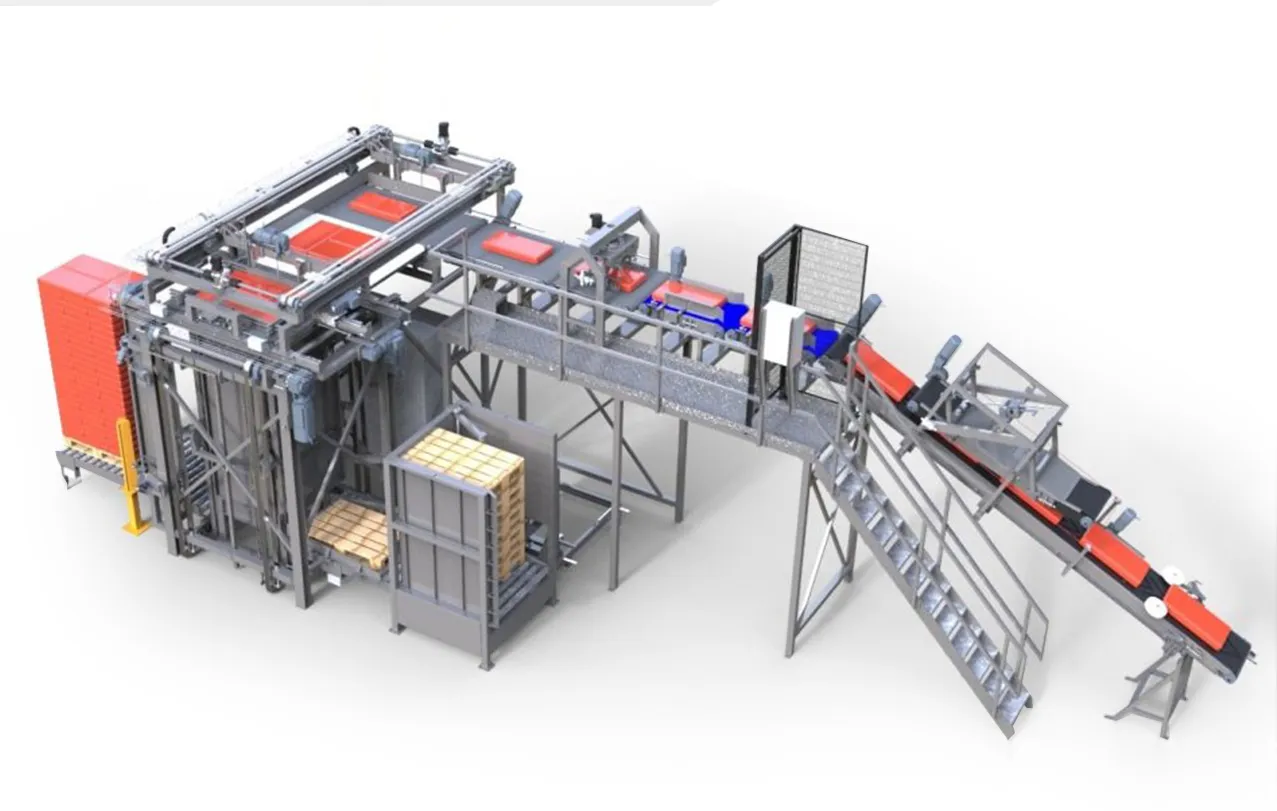

Designed with a turn and sliding mechanism which places complete layers onto the pallet.

- Can process bags, boxes, bales, growbags and more;

- Stacking box to keep the load within the pallet size without overhang, for optimal efficiency in warehouses and containers and no bag damage or product loss.

Designed with a gripping head and bag lifting system that ensures a controlled and accurate bag stacking.

- Perfectly suitable for big and heavy uncontrollable bags;

- Stacking box to keep the load within the pallet size without overhang, for optimal efficiency in warehouses and containers and no bag damage or product loss.

Want to test your products with our machines?

Get in touch with us today

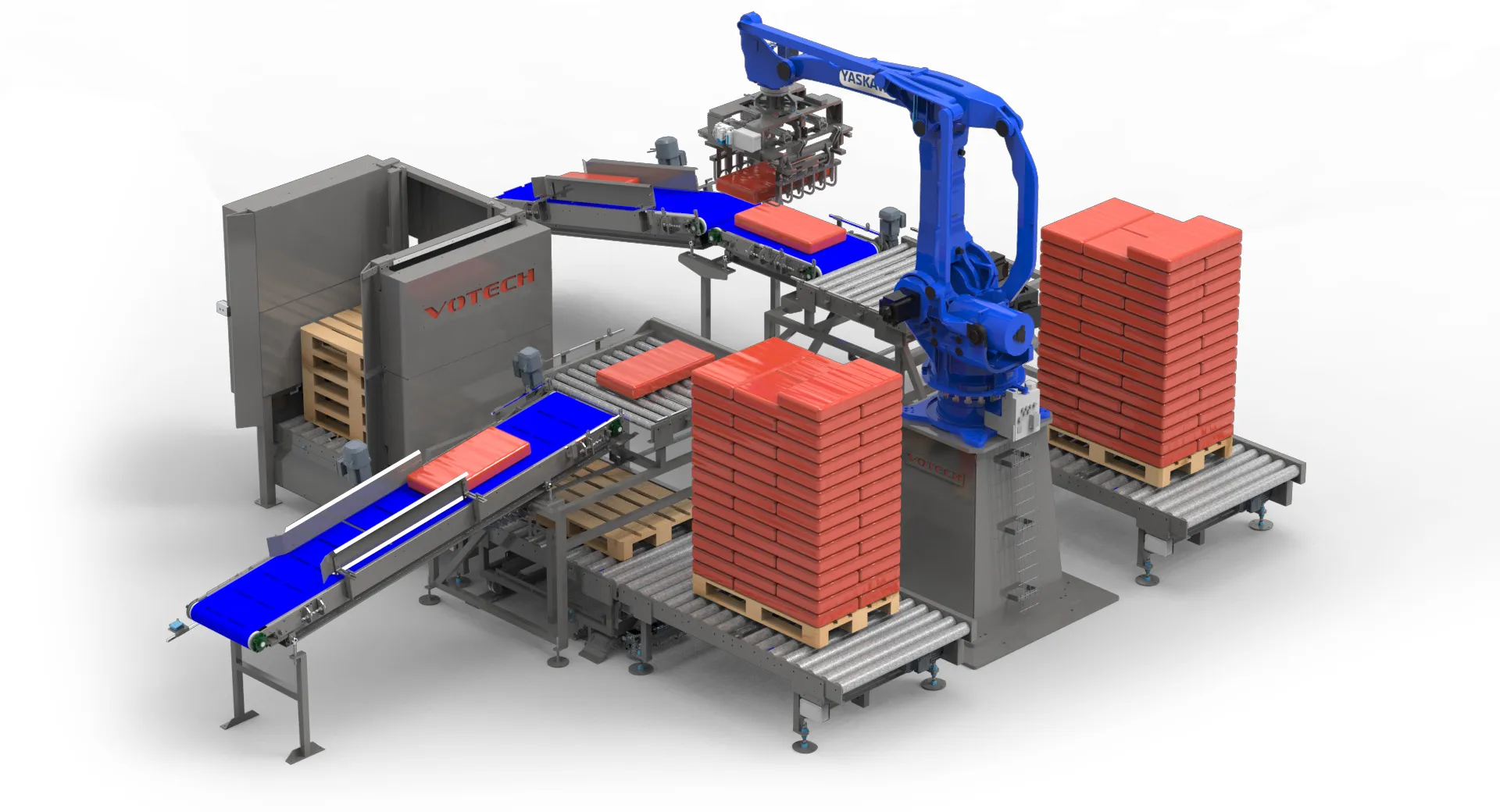

Due to its compact design this palletizer can operate a tight working area with a range up to 360 degrees.

- Can control two lines simultaneously;

- Variety of gripping possibilities such as a gripper head, by vacuum, sliding plate and vertical moving arm.

Contact us now

Palletizing systems for different bag sizes and industries

Every palletizer from Votech is built for efficient, accurate, and stable stacking. Based on your product, bag type, size, and required capacity, we offer various palletizing systems. These systems combine robust mechanical components with intelligent software features, such as graphic stacking pattern controls and frequency-controlled turning heads for precise bag placement. All our palletizer machines are developed and manufactured in-house at our facility in Reusel, and are used globally for palletizing bags in sectors such as:

- Powders and minerals

- Animal feed and pet food

- Agricultural products like seeds and grains

- Horticultural products like potting soil and bark

- And more

With over 1,000 successful projects worldwide, Votech is the trusted partner for your next palletizing system.

Industries

Robot palletizer: flexible palletizing of bags and boxes

In production environments where flexibility is key, Votech offers advanced robot palletizers. Each robot palletizer machine is equipped with cutting-edge technology and a compact design that allows for a 360° working range. This enables the robot to service two lines simultaneously.

These palletizing robots are ideal where hygiene, reliability, and flexibility are crucial. As with our conventional automatic palletizer machines, we ensure full system integration, including pallet roller conveyors and chain conveyors. Robot palletizers can be easily programmed for various product sizes, making them perfect for businesses dealing with a wide variety of bags, boxes, or other packaging types. Multiple production lines can be handled efficiently with minimal changeover time.

Complete palletizing solutions with service and support

Whichever configuration you choose, with Votech’s palletizers and robot palletizers, you’re guaranteed a future-proof, reliable solution for palletizing bags and palletizing boxes. Through our Duravant Lifecycle Services program, we offer 24/7 support—both remotely and on-site—ensuring your palletizing line runs smoothly around the clock.

Frequently asked questions

What is a palletizer machine and how does it work?

A palletizer automates the stacking of bags on pallets according to a preset pattern. The process begins with the supply of products via a conveyor belt. The bags are then positioned using a rotary head or robot arm. They are then neatly stacked on the pallet. Finally, the pallets are automatically transported away via a pallet roller conveyor.

What types of palletizer machines are there?

There are various types of palletizing machines, depending on the product type, desired stacking pattern, and required capacity. Votech offers both conventional and robotic palletizers, each with its own advantages. Conventional palletizers are designed for high capacities and ensure stable and efficient stacking of bags. A full layer of bags is formed and placed onto the pallet in a single motion. These so-called layer palletizers are particularly suited for fixed stacking patterns and offer speed and consistency. Robotic palletizers use a robotic arm to pick up and place bags one by one. This approach offers great flexibility when working with varying bag sizes or in areas with limited floor space. Both systems can be easily integrated into an existing packaging line. The choice between a conventional or robotic palletizer depends on the specific requirements of the production environment, such as capacity, available space, and product variation.

What are the benefits of using a palletizer machine?

Palletizer machines improve the speed, accuracy, and safety of the stacking process. They ensure consistent and stable stacks that are suitable for transport and storage. Automation reduces physical strain on employees, improves hygiene, and maximizes pallet space usage. With high capacities and fast changeovers, they enhance production efficiency and continuity.

How do I choose the right palletizer for my business?

The right choice depends on your product type, size, weight, and required throughput. For bags, a conventional palletizer may be suitable, while a robot palletizer offers more flexibility and saves space. Available floor space and industry-specific requirements also play a role. Votech provides tailored advice to help you select a machine that integrates seamlessly into your line—ensuring a future-proof solution.

What are the maintenance requirements for palletizer machines?

Proper maintenance is essential for reliable performance and a long machine life. Votech machines are designed for easy maintenance and minimal downtime. Key tasks include lubricating moving parts, checking sensors and grippers, and performing scheduled preventive maintenance. In case of issues or upgrades, Votech provides 24/7 service support to keep your production running smoothly.

Can palletizer machines be integrated with existing systems?

Yes, Votech palletizer machines are modular and easy to integrate into both new and existing packaging lines. They connect seamlessly with filling machines, bag closers, pallet roller conveyors, stretch hooders, and more. With smart controls and flexible design, they ensure smooth system integration. Votech supports the full integration process—from design to installation—ensuring uninterrupted and efficient operation.

Are there specific safety standards for palletizer machines?

Votech palletizers comply with strict industrial safety and quality standards. All machines are built in accordance with CE marking and European Machinery Directives. Emergency stop systems and safety interlocks come standard. Additional protection is provided by safety fences and light curtains.